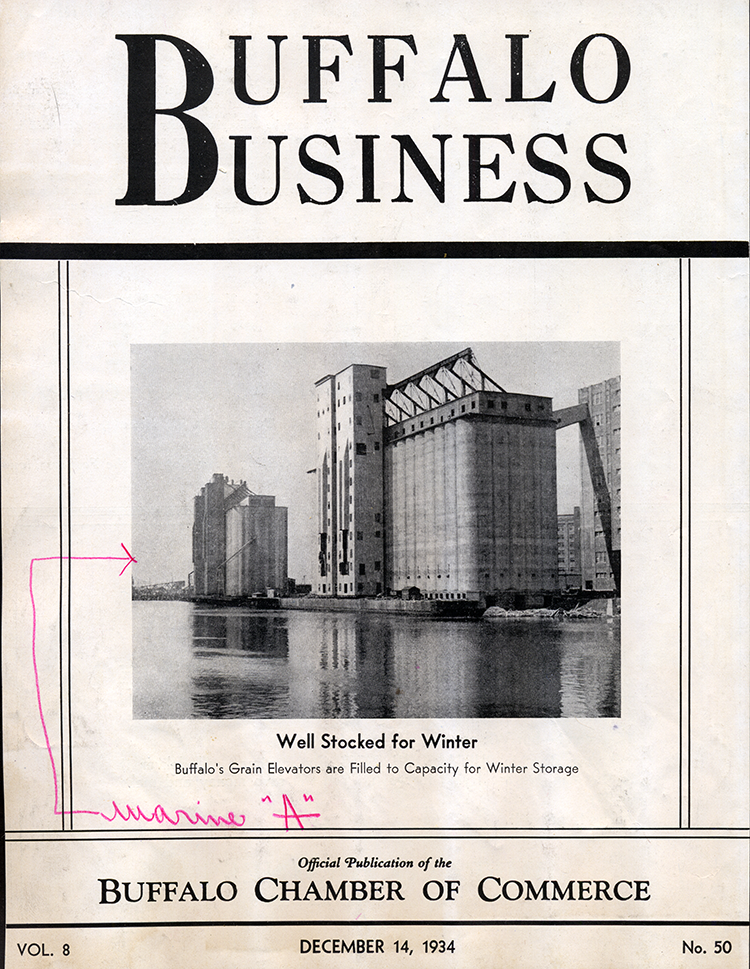

Winter Grain Activity (1934)

Cover Chamber of Commerce magazine, 1934 (red label original) Image source: private collection

Buffalo in 1934 was the flour-milling capital of the U.S., having passed Minneapolis for that title in 1930. In 1931, Buffalo had 38 grain elevators with a capacity of 47,000,000 bushels. Below is an article from the January 7, 1934 Courier-Express on the activity along Buffalo's waterfront.

Plowing its way through ice in Buffalo Harbor, the tug Georgia is shown paving a pathway for the freighter John Stanton, en route from the breakwall to the Marine A Elevator to discharge a cargo of winter storage grain.

By FrancisJ. O'Connell

The question often has been asked: "What's doing on the waterfront after thelake boats layup?"

Little as far as lake activities are concerned. Inside harbor activities, however, are brisk during the winter months and a day seldom passes when the shrill toot of a tug cannot be heard.

These tugs, owned by the Great Lakes Towing Company of Cleveland, of which the Hand & Johnson line at the foot of Michigan Avenue is a subsidiary, can be seen daily plowing their way through six or eight inches of harbor ice. At the end of a tow line extending from the stern of the tug can be seen one of the many 600-foot freighters in winter layup in Buffalo. "Dead" freighters they are sometimes referred to because they have neither a crew on board or steam up.

The tugs are manned by crews as efficient as any to be found in any port on the Great Lakes. At a tug line gathering not so long ago, Louis Lawton, manager of the tug line, referred to his men as the "best group of tugmen on the Great Lakes." And he meant it.

The efficiency with which the tugs are handled is the main reason why a mishap is so seldom, if ever, recorded in the towing of freighters. Regardless of whether the harbor is free of ice or frozen to depth of a foot, the sharp bows of the tugs, ably manned, blast their way through, paving a pathway for the passage of the freighter.

This winter, as in past winters. there is plenty of work for the tugs. Seventy winter storage grain boats are moored in the harbor and at the breakwall. These boats must all be unloaded before the curtain rises on another season of navigation. One by one, they must be brought in from their winter berths, placed at elevators, unloaded and then returned to their berths.

Alongside the tug line at the foot of Michigan Avenue are moored the tugs of the Hand & Johnson line. Four are kept in commission during the winter months, the Alabama, Colorado, Georgia and Kentucky. Other tugs are moored there in the event of necessity and men are always available to man them.

When a grain concern or individual wants his cargo discharged into an elevator, he notifies the owner of the vessel holidng the cargo. The latter, in turn, notifies Mr. Lawton, who promptly dispatches tugs to bring the boat into the elevator.

Since the close of navigation last month, fifteen of the seventy freighters comprising the winter grain fleet either have been unloaded or now are unloading at the elevators. The remaining fifty five will be unloaded during the next three or four months.

Not all the work of the tugs is confined to towing of the grain boats. Occasionally, when a 60- or 70-mile gale hits the waterfront, freighters break loose from their moorings. It is then the duty of the tugs to restore these boats to their positions. The work is dangerous but does not happen very often, particularly because of the firm manner in which the boats are moored.

After the grain boats are unloaded, the owners may find they are in need of repairs. The tugs then tow them to drydock, another winter activity.

In the past two seasons, the freighter John J. Boland has been operating continuosly between the Lackawanna coal dock and Susquehanna plant, carrying coal cargoes. Usually, the vessel operates under its own power. Winter weather, however, often makes it necessary for a tow to accompany the vessel in order to ensure its safety.