The Many Lives of the King Complex, Rano Street, Buffalo

Part 1: King Sewing Machines/King Radio

W. Grant King Manager, Iroquois Iron Works (Men of Buffalo) |

Morris S. Tremain |

George R. Montgomery President, Montgomery Door & Box Co. (Men of Buffalo) |

In the fall of 1906, W. Grant King, a mechanical engineer, and Morris S. Tremain decided to start a sewing machine factory. They engaged Frederick Muller, a nationally recognized mechanical engineer of sewing machine manufacturing equipment, to design the equipment for the new factory. They called the future factory the W.G. King Company. Eighteen months later, the equipment was finished, the company's named changed to the King Sewing Machine Company, and the location selected: Court Street near Wilkerson Street, adjacent to the Montgomery Box and Lumber Company.

By the turn of the 20th century, the home sewing machine was nearly 50 years old. It had revolutionized the manufacture of clothing, both ready-to-wear and made-to-wear. A seamstress previously devoted 14 hours to the hand sewing of a man's shirt; with a sewing machine, she could do the job in 1 1/4 hours. The Singer Sewing machine company was selling 1 million sewing machines worldwide in 1900. What the King Sewing Machine founders intended to do to break into this market was to sell machines at a low cost, $33, and to sell directly to customers in the "factory-to-family" mode. They would manufacture the industry standard type machine, the vibrating shuttle sewing machine, but with what they hoped were appealing improvements.

T he new company was headed by Buffalo natives: Morris S. Tremain, president; W. Grant King, vice-president/general manager; George R. Montgomery, treasurer; Carleton Smith, secretary; and Robert F. Hall, sales manager.

he new company was headed by Buffalo natives: Morris S. Tremain, president; W. Grant King, vice-president/general manager; George R. Montgomery, treasurer; Carleton Smith, secretary; and Robert F. Hall, sales manager.

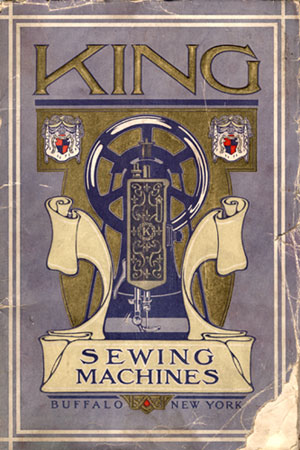

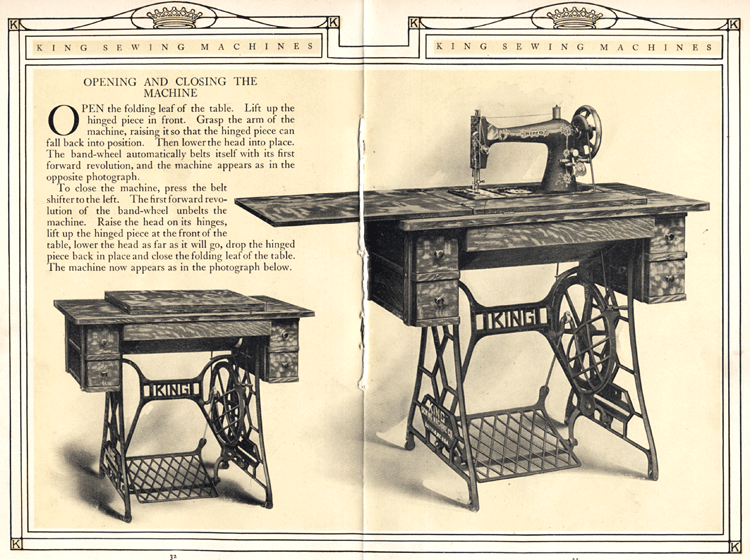

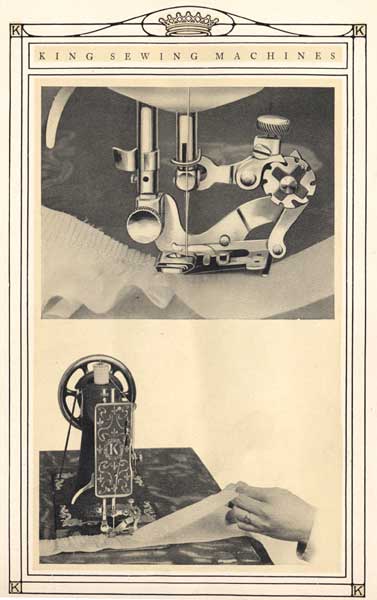

The 66-page sales catalogue (left) was produced in 1908, the year production began. It was expensively produced with numerous photos and, as the authors said, "..we have made the book substantial and beautiful, so that every person who receives a copy will appreciate that is is worth keeping; then, we have filled it with valuable information in such a way that the most inexperienced person can, with a little study, become a skillful operator. We have made it unnecessary to depend on the instruction of a teacher, who says so many things in so short a time that most of them are forgotten. This book says all these things, and it is always at hand in case of need."

The 66-page sales catalogue (left) was produced in 1908, the year production began. It was expensively produced with numerous photos and, as the authors said, "..we have made the book substantial and beautiful, so that every person who receives a copy will appreciate that is is worth keeping; then, we have filled it with valuable information in such a way that the most inexperienced person can, with a little study, become a skillful operator. We have made it unnecessary to depend on the instruction of a teacher, who says so many things in so short a time that most of them are forgotten. This book says all these things, and it is always at hand in case of need."

Pages from the 1908 King Sewing Machine Catalogue. Images source: private collection

|

|

A collector's King sewing machine. Image source: Chrys Gunther on Needlebar

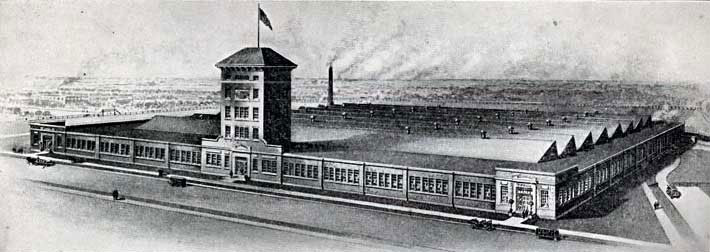

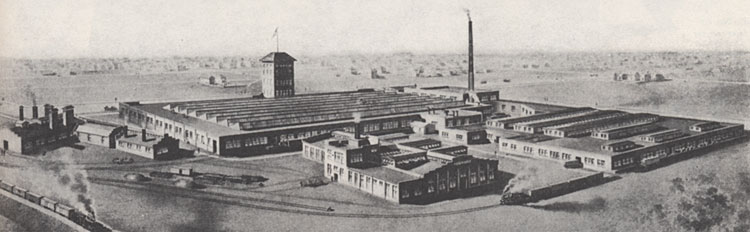

King Sewing Machine Company complex, Rano Street, c 1910. Image source: private collection

The King Sewing Machine Company was most successful in attracting the attention of Sears, Roebuck, & Co. in 1909, which provided the $150,000 capital for King to construct an 8-acre manufacturing complex on Rano Street in Black Rock on land leased from Walter H. Schoellkopf. It was well-located adjacent to the Lackawanna Belt Line. Several city streets were terminated to allow for the $150,000 complex. It was an all-electric factory, which pleased the residential neighborhood. King was now a subsidiary of Sears, Roebuck which contracted for the entire output of the King Sewing Machine Company, to be sold under the Sears brand. Buffalo papers reported that Sears had wanted the factory located in Cleveland, but Buffalo interests persuaded the company to maintain a Buffalo presence. The factory would provide 500-600 full-time jobs. In 1912, the factory expanded, using 500 tons of steel to construct 4 additional buildings.

Tower of the King complex, 2012, with the King Sewing Machine Co. name in terra cotta.

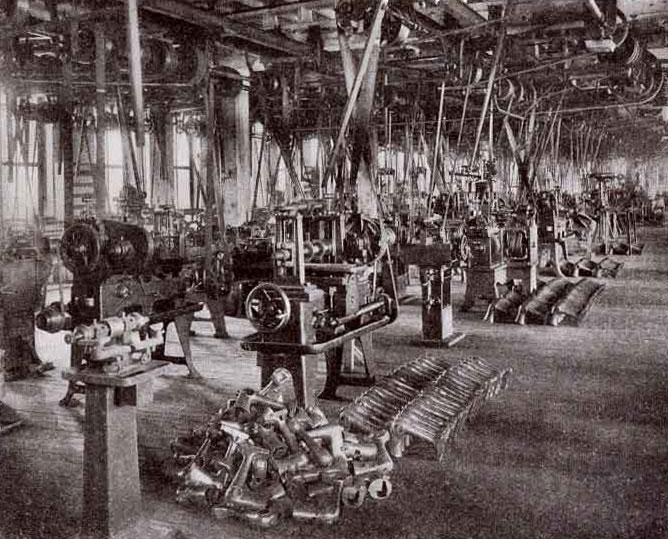

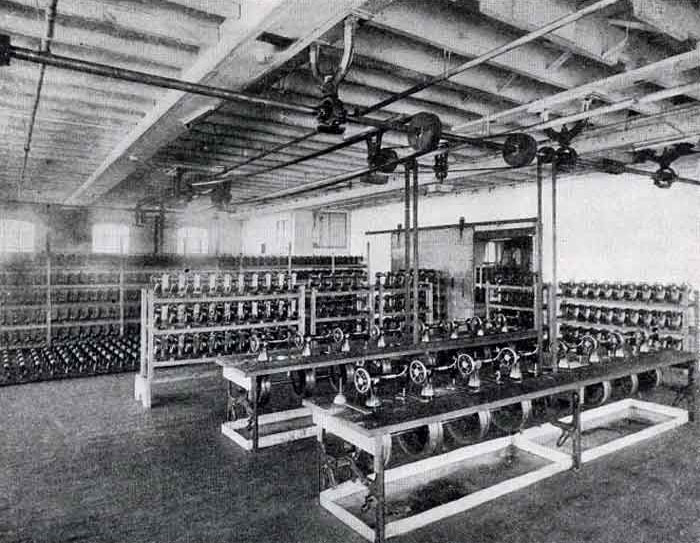

Parts manufacturing area, King Sewing Machine Co. Image source: Chrys Gunther on Needlebar

Sewing machine arm manufacturing room, King Sewing Machine Co. Image source: Chrys Gunther on Needlebar

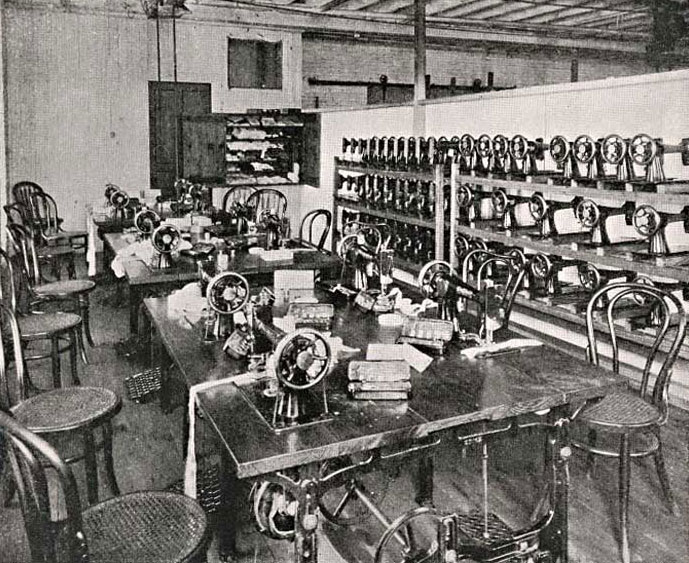

Testing room, King Sewing Machine Co. Image source: Chrys Gunther on Needlebar

Testing room, King Sewing Machine Company. Image source: Chrys Gunther on Needlebar

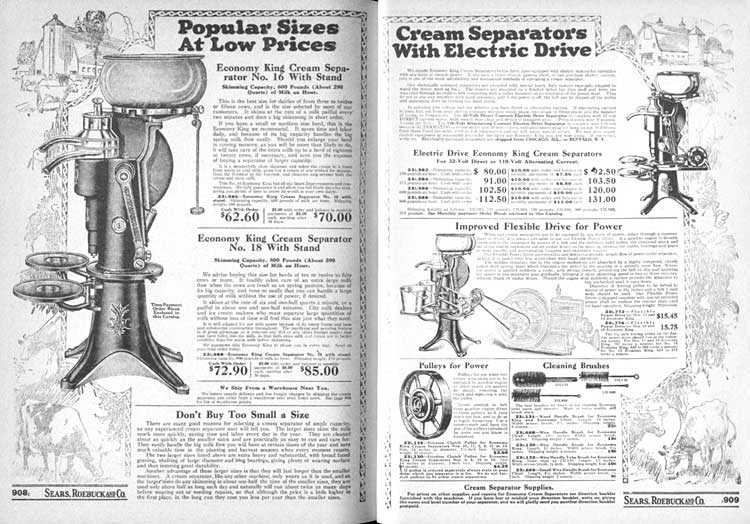

Sears bought cream separators made by the King complex on Rano Street. From the 1923 Sears Catalog.

Image source: private collection.

In 1924, the White Sewing Machine company in Cleveleland acquired the Domestic and King Sewing Machine companies to become the White Sewing Machine Corporation. It supplied Sears, Roebuck.

The King complex on Rano Street became the King Quality Products in 1924. It sold radios through Sears, Roebuck under the "Silvertone" name. King acquired the Neutrodyne license of another company and marketed radios under its own name. The company underwent several name changes: King-Hinners Radio (1926); King-Buffalo (1927); and King Manufacturing Company (1927-30). In 1925-26, the company made 35,000 radio sets in additon to 15,000 for Sears, Roebuck.

King Radio Company complex, viewed from the north. Image source: Radio Manufacturers of the 1920's

1926 advertisement. Click to view larger image. |

1926 advertisement. Click to view larger image. |

The advertisements above are from, "Radio Manufacturers of the 1920s, Volume 2," by Alan Douglas.

Grateful thanks to Alan Quinn of the online museum, Needlebar, and to Chrys Gunther for their permission to use images from Needlebar of the factory interior and a modern photo of a King sewing machine. The css is commented out. remove before publishing!